Sieve analysis of coarse and fine grained soil

Objective and Scope:

The objective of the experiment to determine the grain size distribution of

coarse grain soil by sieving.

Material and

equipment

·

Balance

accurate to 1gm

·

Set

of is sieves

·

Thermostatically

controlled oven

·

Water

tight trays

·

Mechanical

sieve shaker

·

Riffler

Theory:

In order to classify a soil for engineering purpose, one needs to knows the

distributions of the size of grains in soil sample. Sieve analysis is a method

to determine the grain size distribution of soils. Sieves are made of woven

wires with square openings.

The soil is sieved through the set of sieve. The material is retained on

the different sieve is determined. The percentage of material retained in sieve

is given by

Where, Mn=Mass

of soil retained on sieve “

M=Total Mass of soil sample

The results of the

mechanical analysis are plotted to get a particle size distribution curve with

the percentage finer N as the ordinate and the particle diameter as the

abscissa, the dia1neter being plotted on a logarithmic scale. Figure shows some

typical curves for various soils. A particle size distribution curve gives us

an idea about the type and gradation of the soil. A curve situated higher up or

to the left represents a relatively fine grained soil while a curve situated to

the right represents a coarse grained soil.

A soil sample may be

either well graded or poorly graded (uniformly graded). A soil is said to be

well graded when it has good representation of particles of all sizes. On the

other hand, a soil is said to be poorly graded if it has an excess of certain

particles and deficiency of other, or if it has 1nost of the particles of about

the sa1ne size; in the latter case it is known as a uniformly graded soil.

Thus, soil A (Fig) is well graded while soil B is uniformly graded. A curve

with a flat portion represents a soil in which some intermediate size particles

are 1nissing (soil E in Fig.). Such a soil is known as gap graded or skip

graded.

For coarse grained soil, certain particle

sizes such as D10 D30 and D60 are important.

The D10 represents a size, in mm such that 10% of the particle les

are finer than this size. Similarly, the soil particle less finer than D60

size are 60 per cent of the total mass of the sample. The size D 10 is

sometimes called the effective size or effective diameter. The unifbm1ity

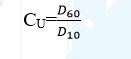

coefficient Cu (or coefficient of uniformity) is a measure of particle size

range and is given by the ratio of D60 and D10 sizes:

Similarly the shape of particles size curve

is represented by the coefficient of curvature is given by ,

For uniformly graded soil CU is equal to unity. For a well graded soil CC

must be equal to 1to 3 in additional CU must be greater than 4 for

gravel and 6 for sands (USBR1960)

Procedure:

For coarse sieve analysis

·

Take the required quantity of sample. Sieve it through a

4.75mm IS sieve. Take the soil fraction retained on 4.75mm IS sieve for the

coarse sieve analysis and that passing through the sieve for the fine sieve

analysis.

·

Sieve the sample through the set of coarse sieve in

mechanical sieve.

·

Determine the mass of the materials retained in each sieve.

·

Calculate the percentage retained through each sieve on the

basis of total mass of the sample taken.

·

Determine the percentage passing through each sieve.

For Fine sieve analysis

·

Take the portion of the soil sample passing 4.75mm IS sieve.

Oven dry it at 105 to 1100C. weight it to 0.1% of the soil mass.

·

Sieve the sample through the set of coarse sieve in

mechanical sieve.

·

Take the material retained on various sieves in a mortar.

Rub it with rubber pestle, but do not try to break individual particles.

·

Revise the materials through the nest of sieve.(minimum 1o

minute od shaking)

·

Collect the soil fraction retained on each sieve in a

separate container. Take the mass

·

Determine the percentage retained, cumulative percentage

retained and percentage finer based on the total mass of sample taken.

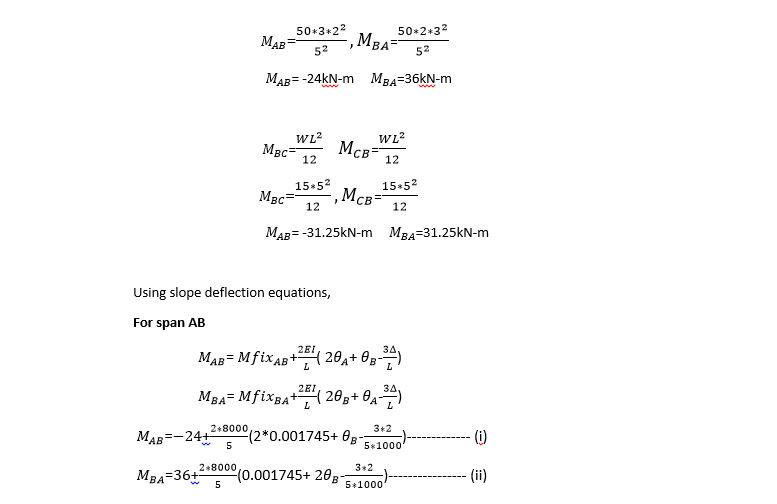

Observation and calculations:

Total mass of Dry soil= 400gm

Mass of soil retained on 4.75mm sieve= 200gm

Mass of soil passing through 4.75mm sieve= 200gm

|

S.N |

|

|

|||

|

IS sieve(mm) |

Mass of soil

retained (gm) |

Percentage

retained (%) |

Cumulative %

retained |

% finer |

|

|

Coarse fraction |

|||||

|

1 |

100 |

- |

|

|

|

|

2 |

80 |

- |

|

|

|

|

3 |

40 |

- |

|

|

|

|

4 |

20 |

30gm |

7.50 |

7.50 |

92.50 |

|

5 |

10 |

62gm |

15.50 |

23.00 |

77.00 |

|

6 |

4.75 |

108gm |

27 |

50.00 |

50.00 |

|

Fine fraction |

|||||

|

7 |

2 |

30.5gm |

7.62 |

57.62 |

42.38 |

|

8 |

1 |

24.0gm |

6.0 |

63.62 |

36.38 |

|

9 |

600µ |

17.5gm |

4.38 |

68.00 |

32.00 |

|

10 |

425µ |

16.0gm |

4.0 |

72.00 |

28.00 |

|

11 |

300µ |

14.0gm |

3.50 |

75.50 |

24.50 |

|

12 |

212µ |

18.0gm |

4.50 |

80.00 |

20.00 |

|

13 |

125µ |

22.0gm |

5.50 |

85.50 |

14.50 |

|

14 |

75µ |

36.0gm |

9.0 |

94.50 |

5.50 |

|

15 |

Pan |

22.0gm |

5.50 |

100.00 |

|

Result:

Percentage finer given in the last column can be used to plot the particle

size distribution curve with particle size as abscissa on log scale and the

percentage finer and ordinate. [Note. If the fine fraction contains as

appreciable amount of clay particles, the wet sieve analysis is required]

Conclusion

................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................